Buckling-Restrained Brace with Elastomeric Layer

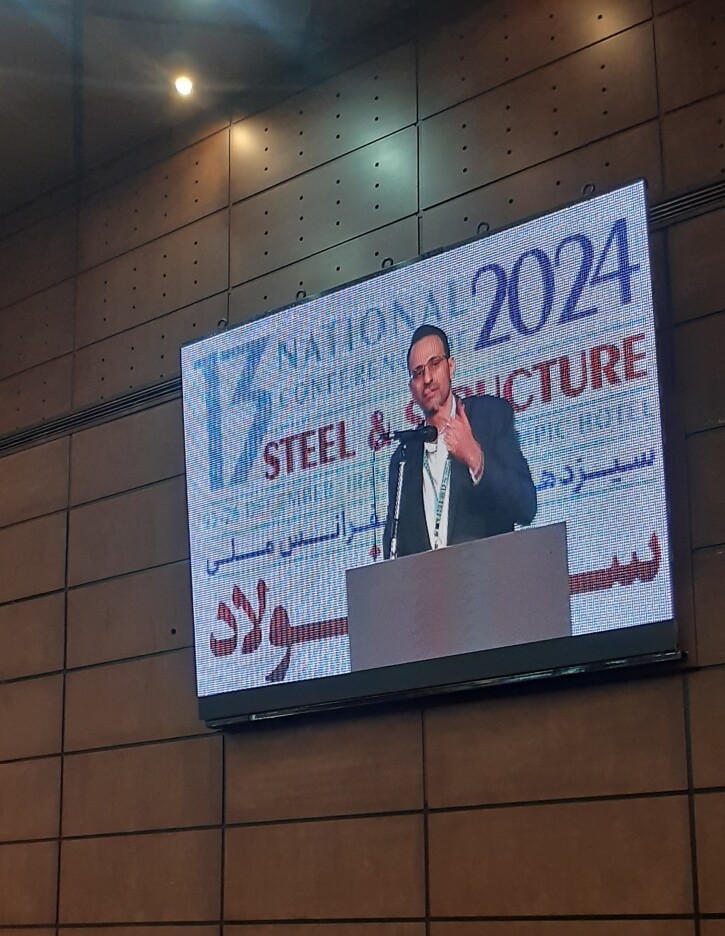

At the 13th Conference on Structures and Steel, Dr. Seyed Ali Razavi introduced an innovative design for enhancing the performance of buckling-restrained braces (BRBs). In his presentation, Dr. Razavi addressed the challenges of traditional BRBs, particularly the reduction in stiffness after yielding, and proposed a new solution incorporating an elastomeric layer to improve system performance significantly.

Proposed Design Structure:

* Dr. Razavi explained that the design features an elastomeric layer between the steel core and the brace casing.

* The elastomeric layer is attached to one side of the casing, while the steel core is connected to the other side of the elastomer.

System Performance:

* Enhanced Stiffness Post-Yielding: The elastomer retains its elastic behavior, compensating for reducing system resistance after yielding.

* Maintained Stability During Core Fracture: The load transfer path through the casing and elastomer ensures structural stability even in critical conditions.

Design Advantages:

- Improved seismic performance of the system

- Enhanced fatigue resistance

- Reduced maintenance and repair costs

- Full compliance with regulatory standards

This innovative design, which garnered significant attention from the conference attendees, not only enhances seismic capabilities but also promises cost reductions in construction and operational phases. Dr. Razavi's presentation was widely praised and highlighted as one of the standout sessions of the conference.